DESCRIZIONE DEL PRODOTTO::

PRIMER EPOSSIDICO PREVENZIONE OSMOSI HS Sea-Line® 3 : 2

| Tipo | laminazione, alluminio acciaio (opzione) | |

| Posto | sotto e sopra la linea di gallegg | |

| Utilizzo | antiosmotic riempimento | |

| Tipo di applicazione e diluizione | NON CONSIGLIATO Opzione – Si, applicazione pennello / rullo | |

| Pennello / Rullo : | Pistola a spruzzo : | |

| 0-5% | NON CONSIGLIATO | |

| Resa teorica 1l | 6 ± 7 m2 150 μm WFT/ 150 μm DFT | |

| Numero di mani | 1 – 4 | |

| Durata della miscela a 20°C | 45 minuti | |

| Intervallo tra applicazioni senza carteggiare a 20°C | min 8 ore max 72 ore | |

Manualmente :

Spruzzo :

DESCRIZIONE DEL PRODOTTO: DILUENTE PER APPLICAZIONE A SPRUZZO che conferiscono al prodotto le giuste caratteristiche di scorrevolezza nell’applicazione , durata […]

PENNELLO PROFESSIONALE Sea-Line® PENNELLO Sea-Line® RULLI Sea-Line® IMPUGNATURA PER RULLI Sea-Line® VASCHETTA PLASTICA Sea-Line® STECCA PER MISCELARE Sea-Line® TAZZE GRADUATE […]

NASTRO DA MASCHERATURA NASTRO DA MASCHERATURA RESISTENTE ALL’ACQUA NASTRO ARGENTO – SPECIALE NASTRO DA MASCHERATURA DESCRIZIONE DEL PRODOTTO: Con buona […]

TAMPONI PER CARTEGGIATURA – sughero naturale TAMPONI PER CARTEGGIATURA – schluma di sughero TELO PROTETTIVO ROTOLO ASCIUGATUTTO PANNI ANTISTATICI TAMPONI […]

MASCHERINA GUANTI MONOUSO IN NITRILE “MASTER” GUANTI MONOUSO IN NITRILE WORKWEAR – SINGLE USE POLYESTER WORKWEAR (blue) reusable overall PASTE […]

PRIMER EPOSSIDICO ANTICORROSIONE Sea-Line® 4 : 1 DESCRIZIONE DEL PRODOTTO:: primer epossidico bicomponente anticorrosione raccomandato come primer per acciaio ed […]

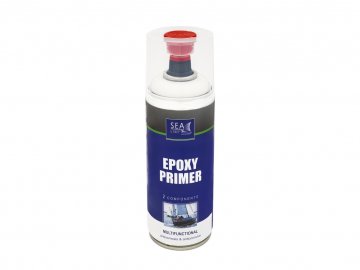

EPOXY PRIMER MULTIFUNCTIONAL 2K SPRAY PRODUCT DISCRIPTION: Multifunctional two components epoxy primer in spray can Simple activating system for two […]

DESCRIZIONE DEL PRODOTTO: DILUENTE PER APPLICAZIONE A SPRUZZO che conferiscono al prodotto le giuste caratteristiche di scorrevolezza nell’applicazione , durata […]

DESCRIZIONE DEL PRODOTTO: Raccomndato per sgrassare le superfici prima delle applicazioni. CONFEZIONE / CODICE: 1 l / CODICE : 3990 INFORMAZIONI […]

Yes, you can paint the bottom of the boat with polyurethane paint due to its high mechanical strength. We recommend this solution when the boat is not launched for a long time and is not exposed to fouling.

Il patch e compensare le irregolarità derivanti da danni durante la produzione

Barca protezione superficiale contro l’influenza di azioni distruttive di osmosi e la corrosione in ambienti difficili

Protezione contro l’acqua e contro gli effetti negativi delle radiazioni UV

Proteggere la parte inferiore della barca prima-tedesco ricoperta di alghe e conchiglie. La prevenzione dell’azione di acqua.

Rimozione efficace di ritenzione graffi, di aggiornamento e il colore del mantello gel o lacca

Laminazione, incollaggio e tappatura perdite

Per il riempimento di piccole fessure e ubyt gemme in gelcoat

Una gamma di prodotti utili quando si lavora costruttore di barche