DESCRIZIONE DEL PRODOTTO:

INFORMACIONI DI BASE:

PRIMER EPOSSIDICO LIGHTPRIMER 5:1

| Tipo | laminazione, legno, alluminio acciaio (opzione) | |

| Posto | sotto e sopra la linea di gallegg | |

| Utilizzo | messa a terra intercoating cappa di riempimento antiosmotic | |

| Tipo di applicazione e diluizione | Si | |

| Pennello / Rullo : | Pistola a spruzzo : | |

| 5-25% | 5-50% | |

| Resa teorica 1l | 11-10 m2 90 μm WFT/ 60 μm DFT | |

| Numero di mani | 1 – 5 | |

| Durata della miscela a 20°C | 2 h | |

| Intervallo tra applicazioni senza carteggiare a 20°C | min 8 ore max 5 giomi | |

PRIMER EPOSSIDICO LIGHTPRIMER 5:1 aplicazione pennello / rolo :

PRIMER EPOSSIDICO LIGHTPRIMER 5:1 aplicazione pistola a spruzzo:

Manualmente :

Spruzz0 :

INFORMAZIONI TECNICHE :

DESCRIZIONE DEL PRODOTTO: DILUENTE PER APPLICAZIONE A SPRUZZO che conferiscono al prodotto le giuste caratteristiche di scorrevolezza nell’applicazione , durata […]

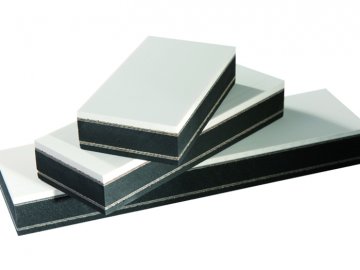

TAMPONI PER CARTEGGIATURA – sughero naturale TAMPONI PER CARTEGGIATURA – schluma di sughero TELO PROTETTIVO ROTOLO ASCIUGATUTTO PANNI ANTISTATICI TAMPONI […]

DESCRIZIONE DEL PRODOTTO: Raccomndato per sgrassare le superfici prima delle applicazioni. CONFEZIONE / CODICE: 1 l / CODICE : 3990 INFORMAZIONI […]

1-component chlorinated rubber primer Recommended above and under the water line It can be use on GRP, steel and wood […]

PRIMER EPOSSIDICO PREVENZIONE OSMOSI HS Sea-Line® 3 : 2 DESCRIZIONE DEL PRODOTTO:: primer epossidico bicomponente ad alto spessore non contiene […]

There is a possibility of thinning antifouling, but we do not recommend this procedure due to the risk of reducing the effectiveness of the paint. If it is necessary to thin the antifouling paint, it is recommended to dilute it to a maximum of 0-5% (by volume).

Il patch e compensare le irregolarità derivanti da danni durante la produzione

Barca protezione superficiale contro l’influenza di azioni distruttive di osmosi e la corrosione in ambienti difficili

Protezione contro l’acqua e contro gli effetti negativi delle radiazioni UV

Proteggere la parte inferiore della barca prima-tedesco ricoperta di alghe e conchiglie. La prevenzione dell’azione di acqua.

Rimozione efficace di ritenzione graffi, di aggiornamento e il colore del mantello gel o lacca

Laminazione, incollaggio e tappatura perdite

Per il riempimento di piccole fessure e ubyt gemme in gelcoat

Una gamma di prodotti utili quando si lavora costruttore di barche