High-quality masking tape characterized by very good adhesion on irregular surfaces, easy to remove without leave any adhesive residue. Saturated paper backing makes tape compatible with most common paints and lacquers. Heat resistant up to 800C. Backing: yellow saturated crepe paper, adhesive: rubber solvent based.

| 19 mm x 50 m | 300000530 |

| 25 mm x 50 m | 300000531 |

| 30 mm x 50 m | 300000532 |

| 38 mm x 50 m | 300000533 |

| 50 mm x 50 m | 300000534 |

| 25 mm x 50 m | 300002043 |

Strong tape of universal application, of the width of 50mm and the length of 25 m, with the allocation for metal, plastic, rubber, waterproof, of silver colour, irreplaceable in automotive industry and household.

| 25 mm x 50 m | 300002931 |

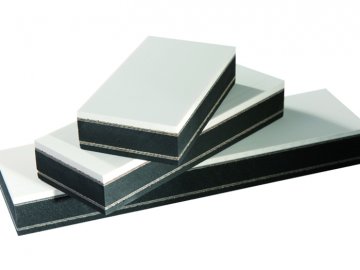

CORK SANDING BLOCK FOAM SANDING BLOCK PLASTIC SANDING BLOCK PROTECTIVE FOIL PAPER TOWEL (ROLL) ANTISTATIC RAGS CORK SANDING BLOCK Sanding […]

GLASS FIBRE MATE Glass fibre mat, in connection with laminating resin, is used for the repairs of big holes in […]

BRUSH PROFESSIONAL Sea-Line® BRUSH Sea-Line® ROLL AND HOLDER ROLL Sea-Line® PAINT TRAY Sea-Line® MIXER FOR PAINT Sea-Line® STORAGE – PLASTIC […]

It is very important to use paint thinners, which provide the appropriate parameters of paint – flow, potlife, time of […]

Sea-Line HARD and Sea-Line self-polishing antifouling are not intended for aluminum surfaces. They include copper oxide, which in contact with aluminum causes galvanic corrosion. Especially on aluminum, we offer ALU-PLUS self-polishing anti-fouling paint, which, in addition to excellent adhesion to aluminum, is also 30% more effective than traditional anti-fouling paints.

Refilling and to tackle inequalities caused by damage to or during the course of production

Protects boat surfaces from the effects of destructive activities osmosis and corrosion

Provide an aesthetic and a perfect look of the boat also protective against water and UV radiation

Protect the hull from fouling with algae and shells

Effectively remove scratches, refresh the color of gelcoat or paint, fast shine effect

Special preparations for effective cleaning and refinishing

Laminating, gluing and filling in cracks in gelcoat

Range of products useful in the boat builder work