Taśma lakiernicza – maskująca, o wysokiej jakości, wykazująca bardzo dobrą przyczepność na nieregularnych powierzchniach. Taśma lakiernicza – maskująca jest łatwa do usunięcia bez ryzyka pozostawiania kleju. Dzięki pokryciu papierem nasyconym jest kompatybilna z najbardziej popularnymi farbami i lakierami.

Odpowiednia do napraw przy temperaturze nieprzekraczającej 80°C. Nośnik: żółty płasko krepowany papier, klej: kauczuk naturalny.

| Wymiar | Kod |

|---|---|

| 19 mm x 50 m | 300000530 |

| 25 mm x 50 m | 300000531 |

| 30 mm x 50 m | 300000532 |

| 38 mm x 50 m | 300000533 |

| 50 mm x 50 m | 300000534 |

Taśma lakiernicza- MASTER „AQUA to wodoodporna taśma jednostronnie klejąca. Nie pozostawia kleju na elementach lakierowanych,

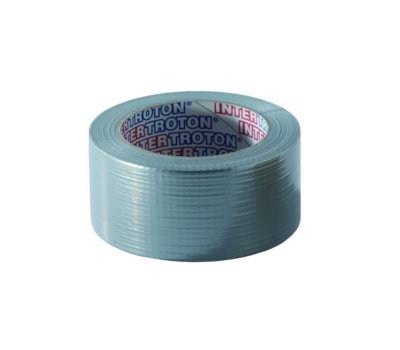

Taśma lakiernicza – SILVER TAPE „UNIWERSALNA” to mocna taśma z szeroką gamą zastosowania. Taśma lakiernicza

Nie prowadzimy sprzedaży detalicznej. Nasze produkty można znaleźć w wielu sklepach w Polsce oraz za granicą. Nasi dystrybutorzy prowadzą sklepy stacjonarne oraz internetowe. Pełną listę dystrybutorów oraz kontakty można znaleźć na naszej stronie internetowej.

Tak, można pomalować dno łodzi farbą poliuretanową ze względu na jej wysoką wytrzymałość mechaniczną. Takie rozwiązanie zalecamy kiedy łódź nie jest wodowana przez dłuższy czas, nie jest narażona na porastanie.

Farby jachtowe Sea-Line przeznaczone są do malowania powierzchni łodzi i jachtów wykonanych z różnego typu materiałów, np. laminat, drewno czy stal. Nie posiadamy certyfikatu Państwowego Zakładu Higieny, który zezwalałby na użycie farby jachtowej do pomalowania zbiornika z wodą pitną.