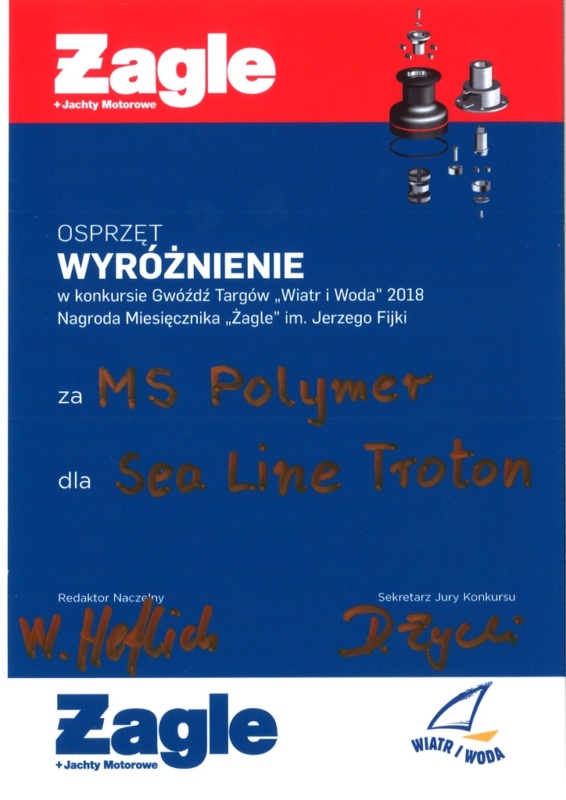

XXX Wind und Water hinter uns. Unter allen Premieren 2018 präsentierten wir die MS POLYMER-Dichtungs- und Klebelösung.

Die innovative Dosierlösung, kombiniert mit den Klebe- und Dichtungseigenschaften von MS POLYMER, wurde in der Kategorie Zubehör und Ausrüstung ausgezeichnet.

Wir sind stolz, Informationen über Trotons Sieg bei den European Business Awards zu teilen. Die

Das Programm „Das Fair-Play-Unternehmen“ wird in Zusammenarbeit mit der Landeswirtschaftskammer geführt. Das Programm wird vom

Der Preis wurde von der Wochenzeitung Newsweek und Kronenberg Stiftung erteilt, die zusammen das Projekt

„Das polnische Erfolg” ist ein Wettbewerb, das polnische Firmen fördert, die eines Wirtschaftserfolgs rühmen können.