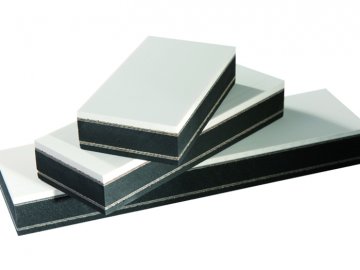

Is elastic sealant recommended for sealing and bonding various types of materials.

POLYMER is recomended for use on :

MS POLYMER

| Type | laminat, steel, wood, concret, plexi, etc. |

| Place | Above and below waterline |

| Function | sealing bonding |

| Chemical character | hybrid |

| Densinity | 1,44 g/cm³ |

| Curing mechanizm | apsorption of moisture from air |

| Elogation at break | to 500% (DIN 53 504) |

| Tensile strenght | 3,0 N/mm² (DIN 53 504) |

| Tear resistance | 20 N/mm |

| Resistant to temperatures | -40ºC to + 90ºC |

| Resistant to temperatures for short intervals | to +120ºC (white, black) |

| to +100ºC (transparent) | |

| Time for skin formation 20ºC | 15 minut |

| Curing time 20ºC | 24 h (weld to 3 mm) |

| Time to contact with water 20ºC | min. 30 minutes |

| Time to be painted 20ºC | 3 day |

| Shrink | no |

WHITE 200 ml / code : 8208

BLACK 200 ml / code : 8210

TRANSPARENT 200 ml / code : 8211

Apply on surfaces no need to priming.

Steel surfaces is recommend to prime using Epoxy Anticorrosion primer 4:1 Sea-Line.

Wood and concrete is recommend to prime using Epoxy Woodprimer 10:4 Sea-Line.

In case of application on natural wood, its humidity should be lower than 20%.

Clean surfaces from rust, damage paint coatings, etc. To increase adhesion, is recommend to sand surfaces by sand paper :

Clean surfaces from dust and contamination.

Grease and salt remove using Cleaner Sea-Line®

Thanks to advance dispensing system, POLYMER does not require extra tools to application, provides exact thickness of weld during application.

unlock nozzle

unlock dosing regulator

set dosing regulator accordance with the needs

apply product by pressing lever

after finishing application, secure dosing nozzle and block dosing regulator

DESCRIZIONE DEL PRODOTTO: Raccomndato per sgrassare le superfici prima delle applicazioni. CONFEZIONE / CODICE: 1 l / CODICE : 3990 INFORMAZIONI […]

MASCHERINA GUANTI MONOUSO IN NITRILE “MASTER” GUANTI MONOUSO IN NITRILE WORKWEAR – SINGLE USE POLYESTER WORKWEAR (blue) reusable overall PASTE […]

TAMPONI PER CARTEGGIATURA – sughero naturale TAMPONI PER CARTEGGIATURA – schluma di sughero TELO PROTETTIVO ROTOLO ASCIUGATUTTO PANNI ANTISTATICI TAMPONI […]

DESCRIZIONE DEL PRODOTTO: nuovo stucco gelcoat è molto veloce nell’essiccazione ed estremamente facile da utilizzare l’induritore è in pasta e […]

DILUENTE PER SMALTI POLIURETANICI COLORATI E TRASPARENTI PER APPLICAZIONE A PENNELLO O RULLO DESCRIZIONE DEL PRODOTTO: che conferiscono al prodotto […]

DESCRIZIONE DEL PRODOTTO : La resina poliestere strutturale Sea-Line è adatta per laminazione, rinforzo delle superfici, riparazioni di fori e […]

Stucco epossidico leggero 1: 1 NUOVO consigliato per grandi aree a causa del basso peso proprio DESCRIZIONE DEL PRODOTTO : […]

We do not recommend degreasing the surface with acetone, because acetone evaporates very quickly, which affects the quality of cleaning the painted surface.

No, polyurethane is a 2-component paint (base + hardener) and after applying 2-component paint to 1-component paint, the proper adhesion of the paint to the surface will not be maintained, the paint will begin to wrinkle and surface defects will appear.

Il patch e compensare le irregolarità derivanti da danni durante la produzione

Barca protezione superficiale contro l’influenza di azioni distruttive di osmosi e la corrosione in ambienti difficili

Protezione contro l’acqua e contro gli effetti negativi delle radiazioni UV

Proteggere la parte inferiore della barca prima-tedesco ricoperta di alghe e conchiglie. La prevenzione dell’azione di acqua.

Rimozione efficace di ritenzione graffi, di aggiornamento e il colore del mantello gel o lacca

Laminazione, incollaggio e tappatura perdite

Per il riempimento di piccole fessure e ubyt gemme in gelcoat

Una gamma di prodotti utili quando si lavora costruttore di barche