| Type | wood | ||

| Place | Above waterline, interior | ||

| Function | High gloss | ||

| Application | brush, roll, spray gun | ||

| Thinning | Thinner for 1 – component primer, varnisch, enamel | ||

| Theoretical coverage for 1l | 12-13 m2 for 80 μm WFT/ 40 μm DFT | ||

| Number of coats | 1 ÷ 3 – renewal old varnish 1 ÷ 5 – new wood, creating new coat | ||

| Dry to the touch 20°C: | 3 h | ||

| Dry to rain 20°C: | 16 h | ||

| Fully woterprof | 24 h | ||

| Elapsed time before applying next coat: | min. 16 h | ||

| Color: | transparent | ||

| Pack : | 0,750 l | ||

| Code: | 300008170 |

It is very important to use paint thinners, which provide the appropriate parameters of paint – flow, pot life, time […]

BROCHA SEA-LINE® PROFESIONAL BROCHA SEA-LINE® RODILLO TERCIOPELO SEA-LINE® BANDEJA PARA PINTURA SEA-LINE® MEZCLADOR DE PINTURA SEA-LINE® VASOS DE PLASTICO GRADUADOS SEA-LINE® COLADOR […]

Aditivo para barnizces superficiales de poliuretano. Polvo antideslizante 20 gramos para 750 ml de poliuretano u otro barniz superficial. Añadir […]

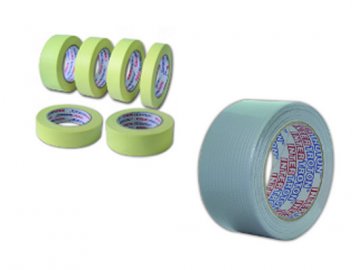

CINTA DE BARNIZAR CINTA DE BARNIZAR IMPERMEABLE MASTER CINTA UNIVERSAL – PLATA CINTA DE BARNIZAR La cinta de barnizar de […]

Mascara para polvo Guantes de nitrilo MASTER Guantes de nitrilo desechables Mono de trabajo desechable Mono de trabajo de poliéster […]

Disolvante para aplicaciones para pistola pinturas y barnices superficiales Disolvante los trabajos es muy importante utilizar el disolvante adecuado lo […]

PRODUCT DISCRIPTION : O1 TEAK OIL is one-component oil for exotic wood which is difficult to impregnate, e.g.: teakwood, mahogany, […]

Producto especialmente recomendado para capa superficial, por encima de la línea de flotación Utilizado para proteger las superficies, frente al […]

Aditivo para barnizces superficiales de poliuretano. Polvo antideslizante 20 gramos para 750 ml de poliuretano u otro barniz superficial. Añadir […]

Para rellenar cavidades y hacer frente a las desigualdades causadas por daños o durante el curso de la producción

Barcos de superficie de impacto de las actividades de ósmosis y la corrosión destructiva en ambientes hostiles

Protección contra el agua y contra los efectos negativos de los rayos UV

Proteger la parte inferior de la embarcación antes de las incrustaciones de algas y conchas. Protección contra el agua

Eliminación efectiva de arañazos, color refrescante y gelcoat brillo o pintura

Preparaciones especializados para la limpieza y restauración efectiva

Laminación, encolado y relleno de fisuras en gelcoat

Una serie de productos útiles durante el constructor de barcos de trabajo